Not the Dodgers, I’m probably more of a Mariners fan, but dodgers, the fiberglass or canvas enclosure installed on a sailboat to help you “dodge” wind, rain and waves. Sojourn’s dodger is in pretty sad shape. It has a flimsy aluminum frame and vinyl windows which were opaque long before joining our family.

I got a quote to have some new windows and zippers put in it, but it came to $400. I just felt that was too much to put in to a faded old piece of canvas with and inadequate frame. So, I decided to fix it myself. I managed to get one of the three windows replaced before destroying my wife’s sewing machine.

Now I needed a sewing machine and a dodger. I went to the only sewing machine store within my radius of traffic tolerance, generally Mukilteo, Everett and Lynnwood. They took one look at my dead machine and said “yeah, plastic frame. We only recommend those to people who want to dip their toe in the proverbial sewing water.” She pointed me to the machine that “all boat owners buy,” a Pfaff Select 3.0. At $600, I was going to be the exception. I had read the blogs and Don Casey’s book, which all said that you could do all of the canvas work you wanted with a $150 classic all metal sewing machine, but with no experience, I couldn’t bring my self to buy one on Ebay without touching it.

I talked her into showing me a very simple $200 metal frame sewing machine. I brought in some canvas to test it. After playing with that for a while, she had me sew a piece of silky delicate material to the end of my folded piece of canvas with the Pfaff. I could feel $600 evaporating from my wallet as the walking foot climbed from the delicate silk to several layers of canvas without a hick up.

One of the other problems with Sojourn’s dodger is that it is at exactly the wrong height. Standing on the cockpit floor, I have to duck or stand on my tippy toes to see forward. I’ve read that it is favorable to be able to look over the dodger. I can’t go up and still fold the dodger because it will interfere with the traveler. Going down would mean bonking my head even more frequently. Sojourn has a tiller, so when I’m sailing, I’m sitting on the combing anyway, so I started looking at concepts that left the dodger up all of the time, only removing the panels when I would otherwise want it down. This got me to thinking about a hard dodger.

With a couple of notable exceptions, most of the DIY hard dodgers I’ve seen are hideous. They are out of proportion and not matching the style of the rest of the boat. Many could easily be bested in workmanship by your average high school shop class. There are also a couple of professionally manufactured fiberglass ones that are out of my price range, but look great, Wavestopper being one of them.

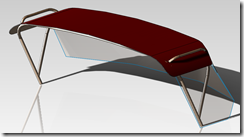

I found one photo of one hard dodger in particular, in a gleaming red and white color scheme much as Sojourn’s. I played around with several variants, all of them too complicated with compound curves. I’m sure they would be beautiful, but it would require a fiberglass mold and more work than I’m willing to invest.

To be candid, looking at Wavestopper got me thinking about a single curve dodger and plywood. I’m not sure why he builds them that way as it sounds like he uses a mold. Perhaps his mold is made from plywood.

My plan is to laminate two pieces of 3 mil Okoume plywood into shape, glass the top and bottom and finish with either one or two part polyurethane.

Here is the current concept. I have the luxury of working with CAD in my daily job so drawing this up and was done in an evening. The outer curves have a 12 inch bend radii.